our journey from fruit to bean to beverage

growing cacao

On the Caribbean side of Costa Rica our farmer and dear friend Daniel South grows a tiny, 2 hectare permaculture cacao farm in the lush, tropical rainforest.

His trees grow in a biodiverse ecosystem among banana and papaya trees and together with a hardworking couple that lives with him on the farm they nurture the trees with great care.

The only fertiliser used is cacao compost that they spread around the tree trunks.

The cacao variety that he calls “old beans” or “Matina” is an heirloom Forastero type. He got the seedlings for his trees from friends and family in the jungle, whereas many indigenous tribes in the area that also grow cacao got their hybridized beans from a government supported program.

Fermenting and sun drying

When perfectly ripe the cacao fruits are handpicked and their seeds are taken out and placed in wooden boxes to ferment for 6 days in order to develop their complex flavours.

On day 7 the seeds are spread on nets to dry naturally in the tropical sun.

Once ready the dried cacao seeds are sorted by hand for impurities, packed in jute bags and shipped to us directly.

roasting cacao

In our production facility in Copenhagen we open the bags and handsort every single cacao bean once again to discard broken shells and odd beans.

Then we gently roast the beans over open fire in a modified coffee roaster.

It is a simple machine with a spinning cast iron drum but it allows us much better control than the traditional flat pans or woks used in Central America. On those pans the roasting temperature is hard to control and the cacao beans often get a bit burned on one side.

With our roaster we can easily change the speed and heat of the roast as we go and thereby fine tune our roasting profiles for the best flavour development.

We roast the cacao beans super light and very carefully and it is a matter of seconds that determines if you hit the perfect spot for each cacao variety. At the end of each roast we keep tasting the beans every few seconds. A bit too much and the cacao tastes burned, a bit too little and you get too much acidity and astringency or no real flavour at all…

Roasting cacao to perfection is indeed a skill that takes time to master!

GRINDING cacao

After roasting we crack the beans into little pieces called cacao nibs and sift away the husk which is bitter and can't be broken down.

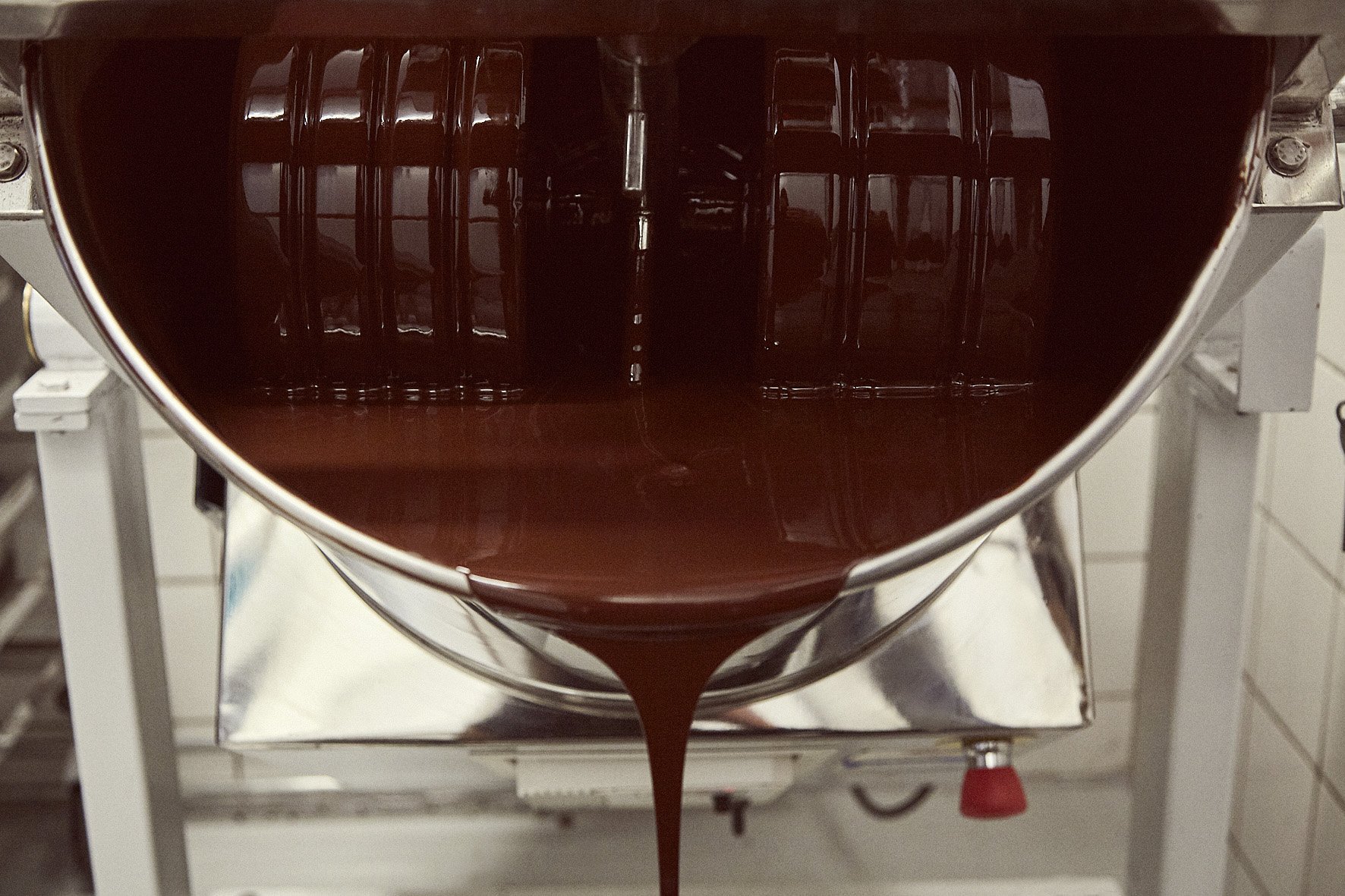

Then we grind the nibs in a very simple stone grinder for 24-48 hours. There is no further heat applied but the friction from the stones releases the oils in the beans, letting the particles refine into pure liquid cacao.

Due to the molecular structure of cacao this liquid slowly solidifies at room temperature resulting in a hard untempered block with its beautiful pattern that some misinterpret for old chocolate.

It is of course just the cacao butter that gathers randomly and when you heat the cacao it once again gets its deep brown colour.

The cacao blocks are then chopped into small pieces and packed in our compostable pouches for you to enjoy!